Industrial burners are critical components in heating systems, furnaces, boilers, ovens, and other industrial applications where precise combustion control is required. To keep these systems operating efficiently, safely, and with minimal downtime, high-quality spare parts play a vital role. Industrial burner spare parts include essential components such as ignition electrodes, gas nozzles, oil nozzles, solenoid valves, flame sensors, pressure switches, filters, gaskets, and control units.Each part is designed to ensure reliable ignition, proper fuel delivery, accurate flame detection, and consistent burner performance. Using genuine and durable spare parts not only extends the lifespan of the burner but also improves energy efficiency, reduces maintenance costs, and ensures compliance with environmental and safety standards. Whether for routine maintenance, emergency repairs, or system upgrades, having the right burner spare parts on hand is crucial for uninterrupted industrial operations.

Burner Head

Domestic Pressure Switch

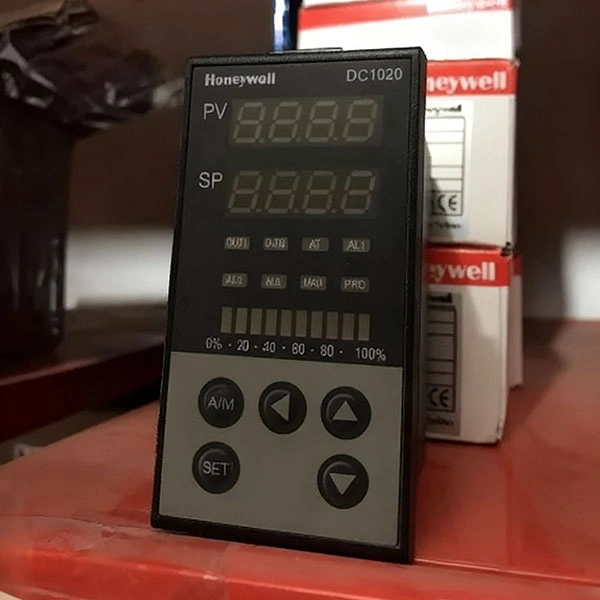

American Honeywell Temperature Controller

Solenoid Valve Plug

Temperature Controller

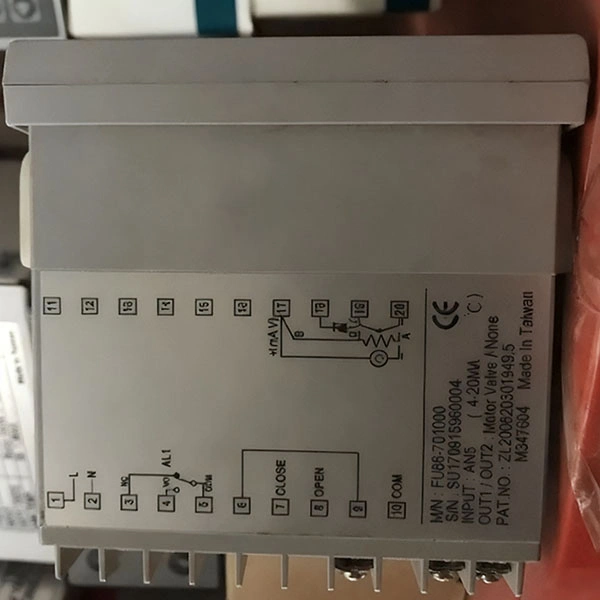

Siemens Damper Actuator

Oil Pipe

Lialu Burner Controller

Metal Oil Pipe

Korean 3S Boiler Pressure Controller

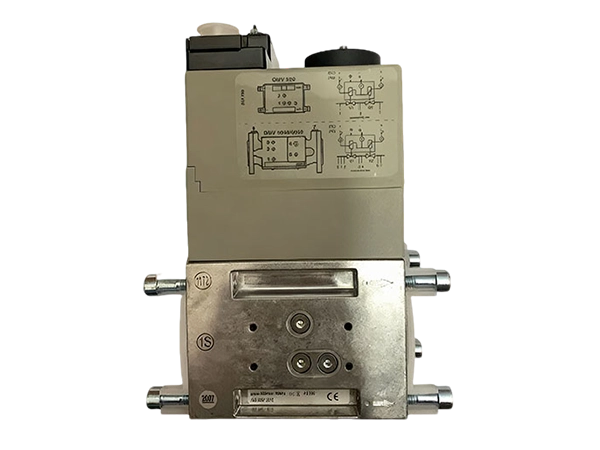

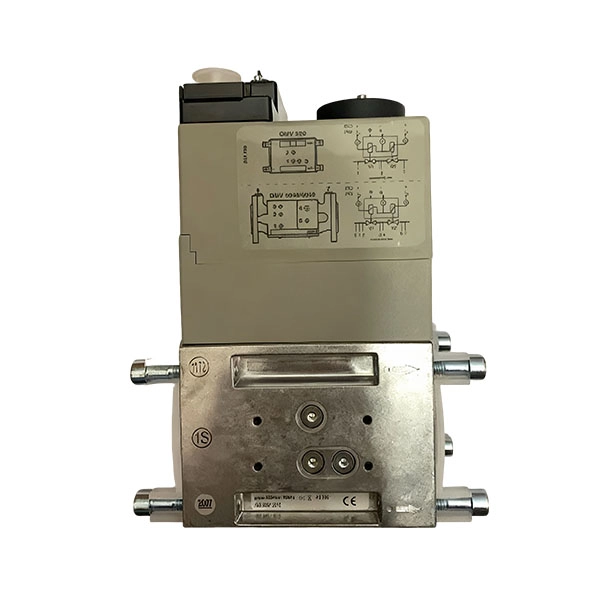

German DUNGS Valve Group

German DUNGS Electromagnetic Quick Opening Valve

Comprehensive Guide to Industrial Gas Burner Operation Safety: Enhancing Production Efficiency and Safety Assurance

In modern industrial production, gas burners are widely used across multiple sectors—including ...

Industrial Oil Burner Maintenance: Tips to Improve Efficiency and Reduce Costs

Industrial oil burners are crucial for manufacturing plants, processing facilities, and large ...

How to Improve Industrial Burner Combustion Efficiency: A Practical Guide for Manufacturers

Industrial burners are the backbone of numerous manufacturing processes, from steel and chemical ...

Difference Between Pressure Jet and Rotary Cup Oil Burners: A Comprehensive Guide for Industrial Applications

Oil burners are a cornerstone of many industrial and commercial heating systems, directly impacting ...

What Is the NOx Emission Standard for Industrial Oil Burners? A Complete Guide for Manufacturers and Plant Operators

In modern industrial production, energy efficiency, environmental protection requirements, and ...

Take every customer request seriously.

Shuxin

Electromechanical

+86 15516359168

shuxin@sxburner.com

Room 504, Building 11, Wuzhou International Industrial Expo City, Old National Highway 310, Xigong District, Luoyang City, Henan Province

+86 15516359168

shuxin@sxburner.com

Room 504, Building 11, Wuzhou International Industrial Expo City, Old National Highway 310, Xigong District, Luoyang City, Henan Province