Rotary kiln incinerators are primarily used to thermally treat solid waste (such as solid waste, waste, and sludge), burning organic matter into harmless carbon dioxide and water while simultaneously treating harmful substances in the organic waste, thereby reducing waste volume and environmental pollution.

A rotary kiln incinerator operates by placing solid waste in a rotating kiln, while providing sufficient oxygen to support the combustion reaction. Under high temperatures (typically between 800°C and 1200°C), the organic matter in the waste is burned into carbon dioxide and water vapor, while the inorganic components are converted into ash or other solid residues.

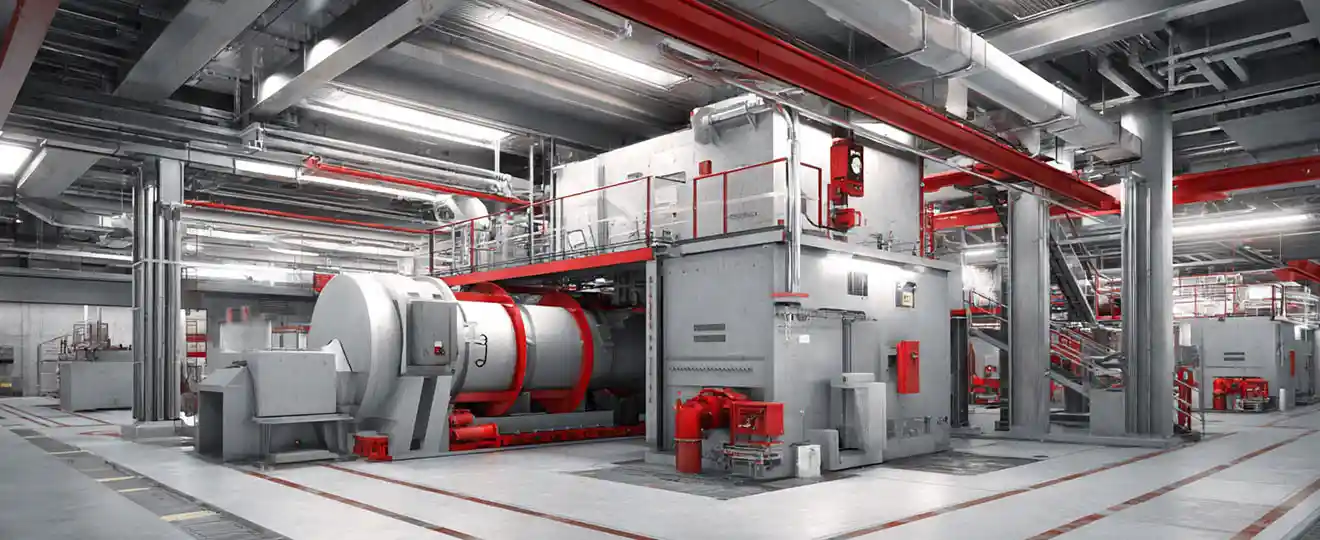

1. Rotary Kiln:

This is the main part of the incinerator, typically a long, inclined cylindrical structure. Solid waste is fed into the rotary kiln and continuously exposed to high temperatures through rotation, promoting combustion and pyrolysis.

2. Burner:

Located at one end of the rotary kiln, it provides fuel and oxygen to form the combustion flame. The burner's design can affect combustion efficiency and stability.

3. Flue Gas Treatment System:

It treats the exhaust gas generated during the incineration process. The flue gas treatment system includes an exhaust gas collection system, exhaust gas purification equipment (such as dust collectors, desulfurization units, and denitrification units), and exhaust piping. These devices effectively remove harmful substances from the exhaust gas, reducing its impact on the environment.

4. Control System:

It monitors and adjusts parameters such as fuel supply, oxygen supply, and rotary kiln speed to ensure stable system operation and meet environmental emission standards. The control system also monitors key parameters such as the rotary kiln's temperature and pressure to ensure safe operation.

1. Preparation:

Inspect key components such as the rotary kiln, burner, exhaust gas treatment system, and control system to ensure proper operation. Prepare the solid waste required for incineration and ensure that waste sorting, processing, and loading are complete.

2. Ignition and Preheating:

Start the burner, ignite the fuel, and provide sufficient oxygen to form a stable flame.

Begin the rotary kiln's rotation and gradually increase the kiln temperature to preheat the kiln. During this stage, waste is added to the kiln.

3. Main Combustion Phase:

When the kiln temperature reaches the required combustion temperature, a large amount of solid waste is added.

The waste continues to heat, burn, and pyrolyze in the kiln, converting organic matter into harmless gases and ash.

4. Waste Gas Treatment:

Waste gas is collected through the waste gas treatment system and undergoes dust removal, desulfurization, and denitrification to ensure that emissions meet environmental standards.

5. Monitoring and Control:

Continuously monitor key parameters such as temperature, pressure, and speed within the rotary kiln to ensure stable system operation.

Adjust parameters such as the burner and rotary kiln speed based on monitoring results to maintain optimal combustion conditions and incineration efficiency.

6. Shutdown:

When waste combustion is complete or shutdown is necessary, gradually reduce the fuel and oxygen supply, and also gradually reduce the rotary kiln's rotation speed.

Shut down the burner and ensure that any remaining fuel in the rotary kiln is completely burned and extinguished.

Shut down the exhaust gas treatment and control systems and perform equipment inspection and maintenance.

During operation of the rotary kiln incinerator, strict control of the combustion process and exhaust gas emissions is required to ensure safe, stable operation of the system and compliance with environmental standards. Through continuous optimization and improvement, the rotary kiln incinerator will continue to play its important role and contribute to environmental protection and sustainable development.

Take every customer request seriously.

Shuxin

Electromechanical

+86 15516359168

shuxin@sxburner.com

Room 504, Building 11, Wuzhou International Industrial Expo City, Old National Highway 310, Xigong District, Luoyang City, Henan Province

+86 15516359168

shuxin@sxburner.com

Room 504, Building 11, Wuzhou International Industrial Expo City, Old National Highway 310, Xigong District, Luoyang City, Henan Province