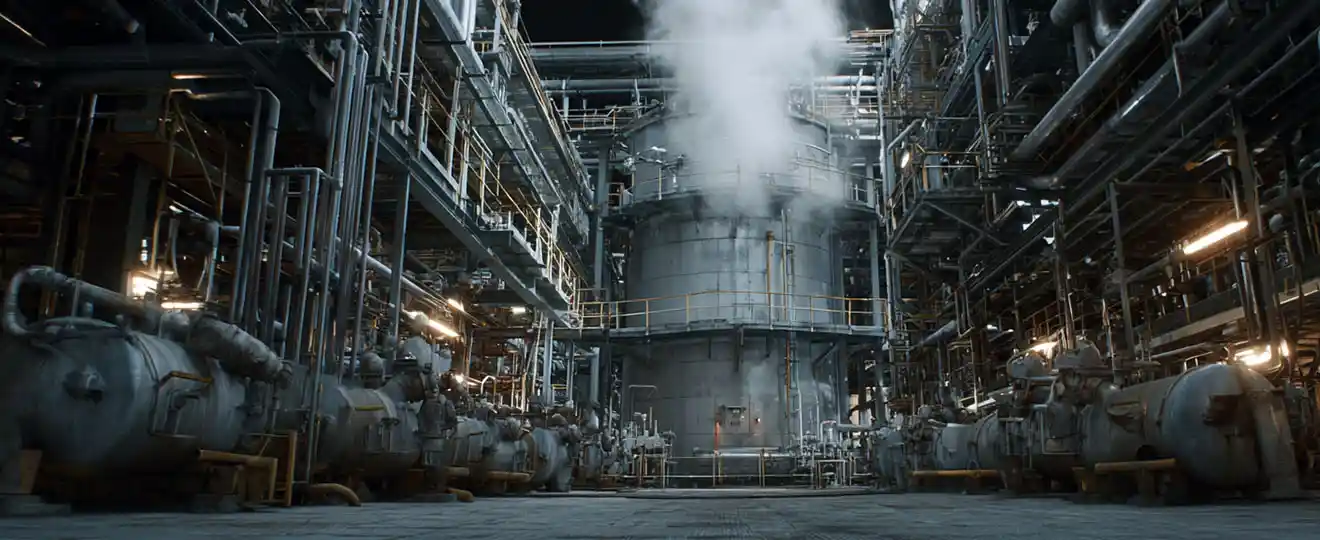

Industrial burners play a crucial role in the steam industry, primarily by generating the heat necessary to produce steam. This steam is then used for a variety of applications, from power generation to heating and various industrial processes.

The most common application is in boilers. Industrial burners fire into a combustion chamber, heating water within the boiler tubes to generate steam. Different types of boilers exist, such as fire-tube and water-tube boilers, and the burner system is designed to integrate seamlessly with each.

Industrial burners are designed to operate on a wide range of fuels, including:

Natural Gas: Clean-burning and efficient, often preferred when available.

Fuel Oil: Various grades (light, heavy) are used, often requiring preheating for heavier oils.

Propane/LPG: Used in areas where natural gas is not available or for specific process needs.

Biomass: Increasingly used for sustainability, requiring specialized burners for solid fuels.

Waste Fuels: In some industries, waste products (e.g., refinery off-gases) can be used as fuel, providing both energy recovery and waste disposal.

Register Burners: Common in larger industrial boilers, these burners mix fuel and air in a controlled manner to achieve efficient combustion.

Low NOx Burners: Designed to minimize the production of nitrogen oxides (NOx), which are environmental pollutants. These are increasingly important due to stricter emission regulations.

Dual Fuel Burners: Capable of firing two different types of fuel (e.g., natural gas and fuel oil), providing operational flexibility and backup in case of fuel supply interruptions.

Staged Combustion Burners: These introduce air in stages to create fuel-rich and fuel-lean zones, which helps in reducing NOx emissions.

Efficiency: Modern industrial burners are designed for high thermal efficiency, meaning they convert a large percentage of the fuel's energy into usable heat for steam generation, reducing operating costs and fuel consumption.

Emissions Control: Beyond NOx, burners are designed to control other emissions like carbon monoxide (CO), particulate matter, and unburnt hydrocarbons.

Reliability and Turndown Ratio: Burners must be reliable for continuous operation and have a good turndown ratio, meaning they can operate efficiently over a wide range of heat output demands.

Safety: Advanced safety systems are integrated with industrial burners to prevent combustion hazards, including flame supervision, interlocks, and purge cycles.

The steam produced by these burners powers various processes:

Power Generation: High-pressure steam drives turbines to generate electricity in power plants.

Process Heating: Steam is used as a heat transfer medium in chemical processing, food and beverage production, pharmaceuticals, and many other manufacturing industries.

Sterilization: In hospitals and certain industries, steam is crucial for sterilization processes.

Humidification: In HVAC systems and some industrial processes, steam is used for humidification.

Mechanical Drive: Steam can directly drive pumps, compressors, and other equipment.

Take every customer request seriously.

Shuxin

Electromechanical

+86 15516359168

shuxin@sxburner.com

Room 504, Building 11, Wuzhou International Industrial Expo City, Old National Highway 310, Xigong District, Luoyang City, Henan Province

+86 15516359168

shuxin@sxburner.com

Room 504, Building 11, Wuzhou International Industrial Expo City, Old National Highway 310, Xigong District, Luoyang City, Henan Province