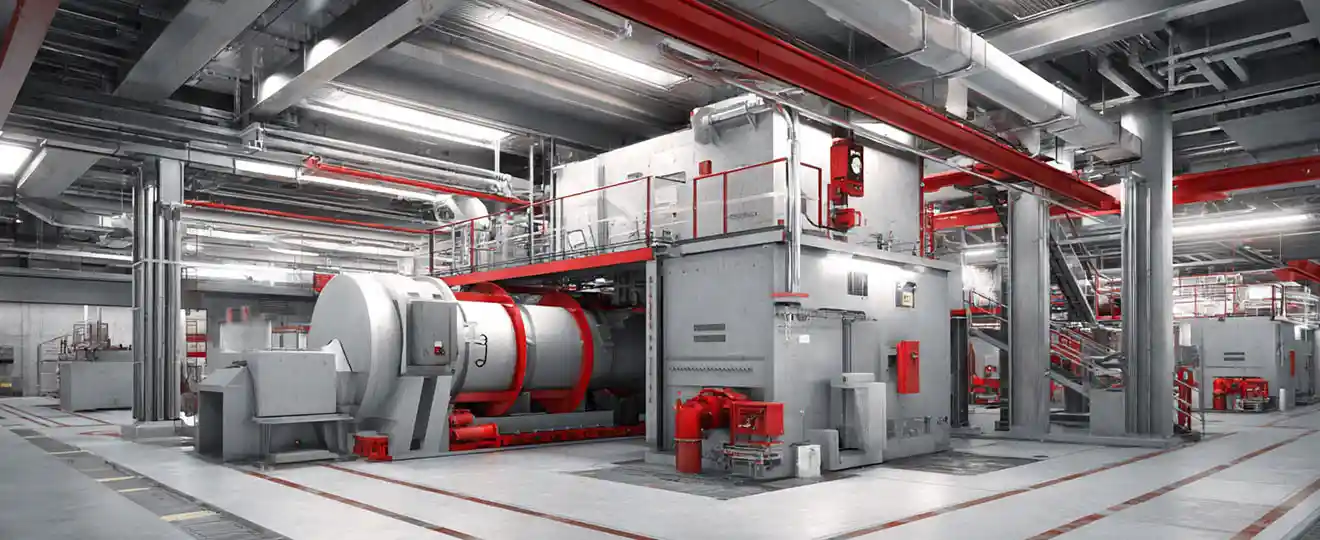

Steel and Metallurgy Industry

Hot air drying, moisture drying, paint powder curing, flat welding, industrial air conditioning and heating, metal melting in industrial kilns, heat treatment, waste gas treatment and incineration, coal to natural gas conversion, electricity to natural gas conversion, industrial furnace emission standards, environmental protection and energy-saving renovation projects, etc.

See More

Dry Food Industry

Food dryers, also known as mesh belt dryers, distribute the material onto a conveyor belt through a suitable spreading mechanism, such as a star-shaped distributor, oscillating belt, grinder, or granulator. The conveyor belt then passes through a channel consisting of one or more heating units. Each heating unit is equipped with an air heating and circulation system, and each channel has one or more dehumidification systems. As the conveyor belt passes, hot air flows from top to bottom or bottom to top through the material, ensuring uniform drying.

See More

Hot Blast Furnace Industry

This method uses direct combustion of fuel, which is then purified to generate hot air, which comes into direct contact with the material for heating, drying, or baking. This method consumes approximately half the fuel of steam-type or other indirect heaters. Therefore, direct, highly purified hot air can be used without compromising the quality of the dried product.

See More

Rotary Kiln Industry

A rotary kiln (commonly known as a rotary kiln) is a type of building materials equipment. Rotary kilns can be categorized as cement kilns, metallurgical and chemical kilns, and lime kilns, depending on the materials they process. Cement kilns are primarily used to calcine cement clinker and are divided into two main types: dry-process and wet-process cement kilns.

See More

RTO Industry

RTO is a highly efficient organic waste gas treatment device. Compared to traditional catalytic combustion and direct-fired thermal oxidizers (TO), it offers high thermal efficiency (≥95%), low operating costs, and the ability to treat high-volume, low-concentration waste gas. For slightly higher concentrations, it can also perform secondary waste heat recovery, significantly reducing production and operating costs.

See More

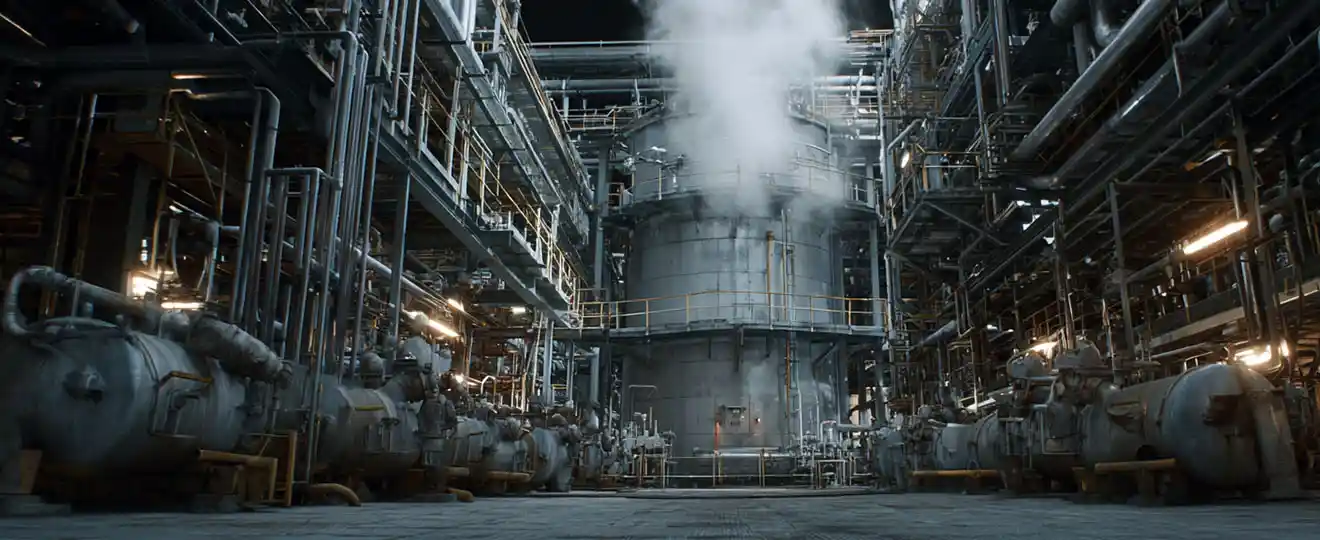

Steam Industry

The application of industrial burners in the steam industry is rapidly developing towards higher efficiency, cleaner operation, and smarter technology. The mature application of low-NOx combustion technology has made it possible to control nitrogen oxide emissions below 30mg/m³. Intelligent control systems enable precise control and remote management of the combustion process, significantly improving energy efficiency.

See MoreTake every customer request seriously.

Shuxin

Electromechanical

+86 15516359168

shuxin@sxburner.com

Room 504, Building 11, Wuzhou International Industrial Expo City, Old National Highway 310, Xigong District, Luoyang City, Henan Province

+86 15516359168

shuxin@sxburner.com

Room 504, Building 11, Wuzhou International Industrial Expo City, Old National Highway 310, Xigong District, Luoyang City, Henan Province